About Cooloo

Cooloo

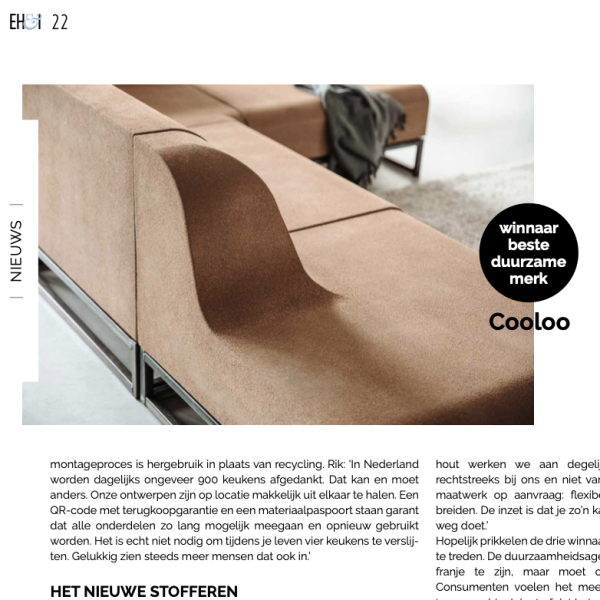

Cooloo transforms local waste into sustainable furniture, interiors, and construction materials for flooring and facades with its Endless Life® technology.

By combining bio-based binders with residuals from fibers like leather, cork, jeans and olive pits, minerals such as limestone and bricks or even metals like copper, iron and aluminium, Cooloo creates sustainable and circular materials.

These materials can be sprayed or applied onto any surface, shape or material. Turning waste into tactile, eye-catching surfaces, enabling a more sustainable future without compromising on aesthetics. The result: beautiful materials and products designed for a fully circular life cycle.

Company introduction

Leo Schraven

CEO

Back in 1984 I started my adventure working in the furniture industry. With a mechanical and chemical background, I gained a lot of material and production knowledge at large furniture manufacturers. Enthusiastic and eager to learn, during quality management projects I was faced with standards and how raw materials are processed throughout the production process.

If we go further back in time, to when we still lived in caves, we get to the core of the current furniture production process. People shot bears; their skins were put on top of rocks with some horse hair in between to increase comfort. Not much has changed. The rock is replaced by trees or steel, the hair by foam. The process has been industrialized but did not evolve.

While working at a large furniture company, I noticed that the production chain has become longer and more complex by maintaining the same principles instead of innovating. If we look at the raw materials’ processing and take leather as an example, then € 1 material costs quickly amount to € 1.48 due to the storage costs. Cutting the leather to size results in a material loss of 35%, and cutting those remains and sewing them together caused absenteeism. The joints’ heavy strain from cutting and stitching became more and more intense as the leather thickened. As a result, employees had to pull harder and harder to tighten the furniture shapes. Around 2000, due to the economic boom, people were not available for production in Europe. By only moving labor to where the workforce was present and not the knowledge, you saw that the production chains only got longer, the losses increased, the quality declined, and the expertise decreased.

This made it clear to me that the expertise should not be maintained or increased, but that the production process had to be tackled. How can we make the product differently? In 2001 the idea arose to coat the leather instead of upholstering it. This inspiration came during the coating of furniture with solvent-based flexible coatings. In the following years, I started to process skins to be able to apply them as a coating completely. In 2012 we began developing coatings from local waste streams. A local leather tanner had a leather waste stream that generally went into the incinerator. We still convert this leather waste stream into our CoolLeather coating. In addition to leather, I also started working with concrete, and we started applying these waste materials to foam. By producing the entire piece of furniture from foam, we have drastically shortened the production chain. For this, we have developed new production techniques in-house, obtaining the suitable fineness, the way of application, sanding, application, quality development, and all this in the most sustainable way possible. We test our coatings using certified testing techniques.

Cooloo’s ecological coatings and the production techniques developed by us fit perfectly in our Endless Life principle. I am convinced that we can give furniture an Endless Life by coating it and keeping production chains as short as possible. As a result, we produce our furniture as sustainably as possible, and it can be recycled or refurbished locally. Coating is the new upholstering!

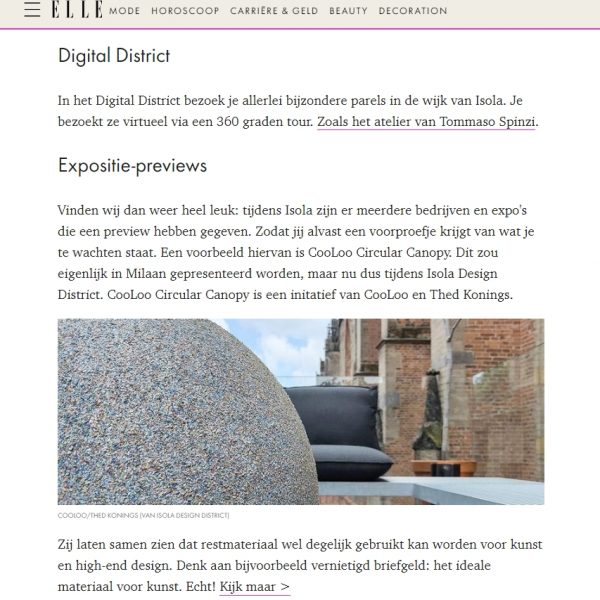

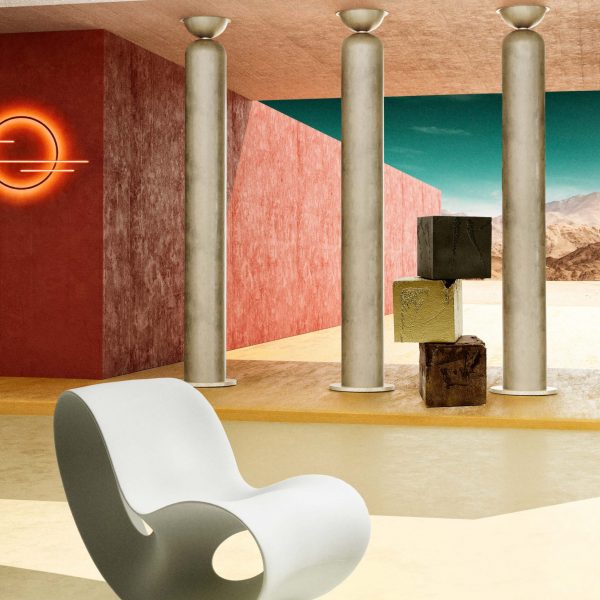

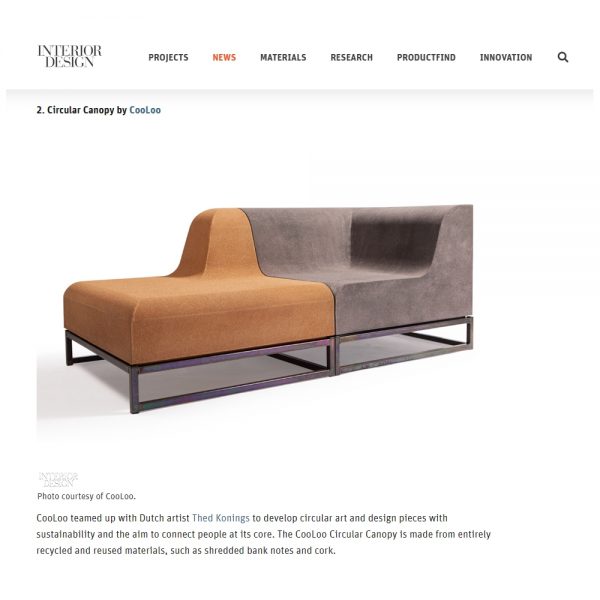

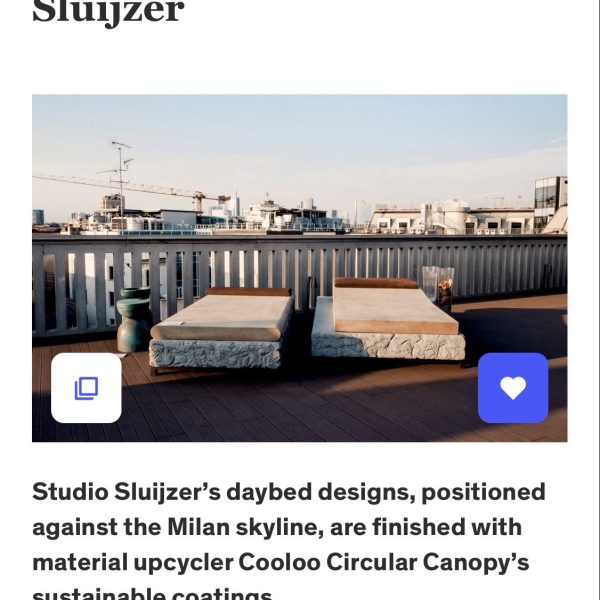

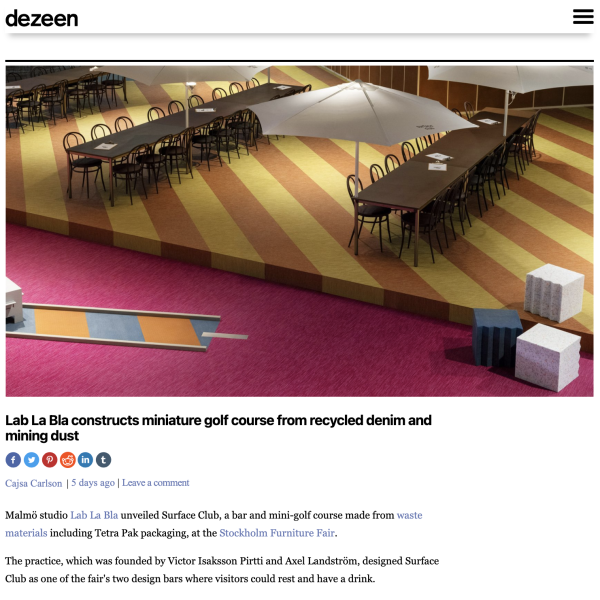

Cooloo Circular Canopy

Cooloo Circular Canopy is an initiative of Dutch designer Thed Konings in co-creation with Cooloo. Together with many partners and designers, they create art and design objects based on sustainability, circularity, and zero-waste. Cooloo Circular Canopy aims to inspire international companies and designers to close the circle around sustainability at the upcoming Salone del Mobile in Milan. Closing the circle by thinking circular.

Contact & Showroom

Awards

2025 – Gold – Other Interior Designs – Temporary / Pop-up from the International Design Awards

2025 – Best Element – EXPO Exhibitor Awards by Exhibitor Magazine

2023 – VTWonen Beste Duurzame Merk

2022 – Circular Innovation Award – Jury prize

2021 – Innovation in Design Award – Isola Design Awards

2020 – Good Industrial Design Award at DDW

2018 – Best Product at Design District